Making Picture Frames - Step 2 -

Routing Profiles

We've made it through Step 1 of making picture frames. Our molding is the same width and thickness.

Now it's time to think about creating the decorative profile that you see on the inside edge of most picture frames.

Create the Inside Decorative Profile

You can do this with a table saw or a router.

If you have a router, my recommendation is to use that.

A router will give you more options and encourage creativity.

I've used the router linked above for many years. I Highly recommended it for its cost, durability and non-stop dependability.

If you don't have a router, a beveled edge, created with the table saw, also makes a beautiful picture frame.

Take a look at your 2 rails carefully. YOU HAVE TO DECIDE NOW which sides will be the front face. Look for flaws, strange grain patterns, sapwood or anything else that you wouldn't want to be seen.

All defects to the back!

Look at the edges too. Are there defects there? Can they be removed when you cut the rabbet? Time spent right now examining the wood pays off big time later. Making picture frames is all about the details.

The Most Versatile Router Bit

For this frame we'll use a simple cove to create our inside profile. As you experiment more with other router bits you can come up with all kinds of cool edge profiles. My favorite router bit though is the Classic Roman Ogee|

With this one bit you can cut the cove on the inside edge AND make several different decorative profiles on the outside edge of your picture frame. Simply move the bit up or down. Just looking at the bit, you can see there are many possibilities. It also helps when you can leave the same router bit in your router for cutting the inside and outside profiles. There's no NEED to have a lot of router bits. |

|

Making Picture Frame Profiles

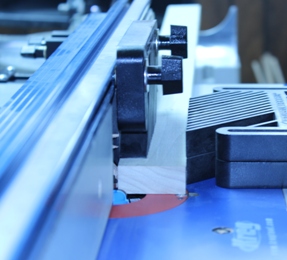

When routing profiles, always take several shallow passes with your router. This helps prevent tearing and splitting of the wood. It also helps reduce the workload on the router.

The cove should be about 1/8" deep, you can adjust if you like, but keep in mind, you have to leave enough wood between the cove and the rabbet which sits below it.

If you cut the cove too deep, you won't be able to cut a rabbet deep enough to hold the glass, mat and back board.

|

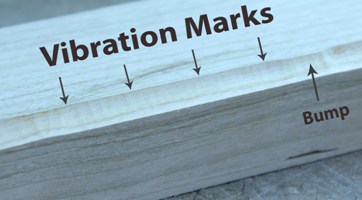

Tip - if you're using a router table, be sure to use feather boards Any movement when passing the rails through the router bit will create bumps and/or vibration marks in the profile - like the ones you see in the picture to the right. You'll have to sand those out, if possible (costing time and money!!) or end up disappointed when you apply the stain and finish. |

|

After each pass, I run my fingers though the cove, feeling for bumps or vibration marks. If I find any, I make another pass through the router making sure the rail is tight to the fence, before I make the next, deeper cut.

If you do that every time, you'll have nice, smooth, finish ready cove profiles on your picture frames.

|

Tip - when I first started making picture frames, I would route the outside profiles during this stage too. It caused a lot of frustration though when I reached the glue-up stage. Many times, the profiles from one rail to the next didn't line up exactly. That's NO GOOD. Then I tried gluing up the rails BEFORE routing the outside edges... |

|

...and what do you know? They come out perfect every time!

Making picture frames is even more enjoyable when you eliminate some of the potential mistakes before they happen!

OK, the inside coves are cut and smooth. We're on our way to Step 3, like Easter Sunday, rabbets become our focus… Oh boy… :)

|

Classic Roman Ogee |

Cove Cutting Bit |

Bevel Edge Bit |

Have a question or a comment? This space is for you! Leave it in the box below.